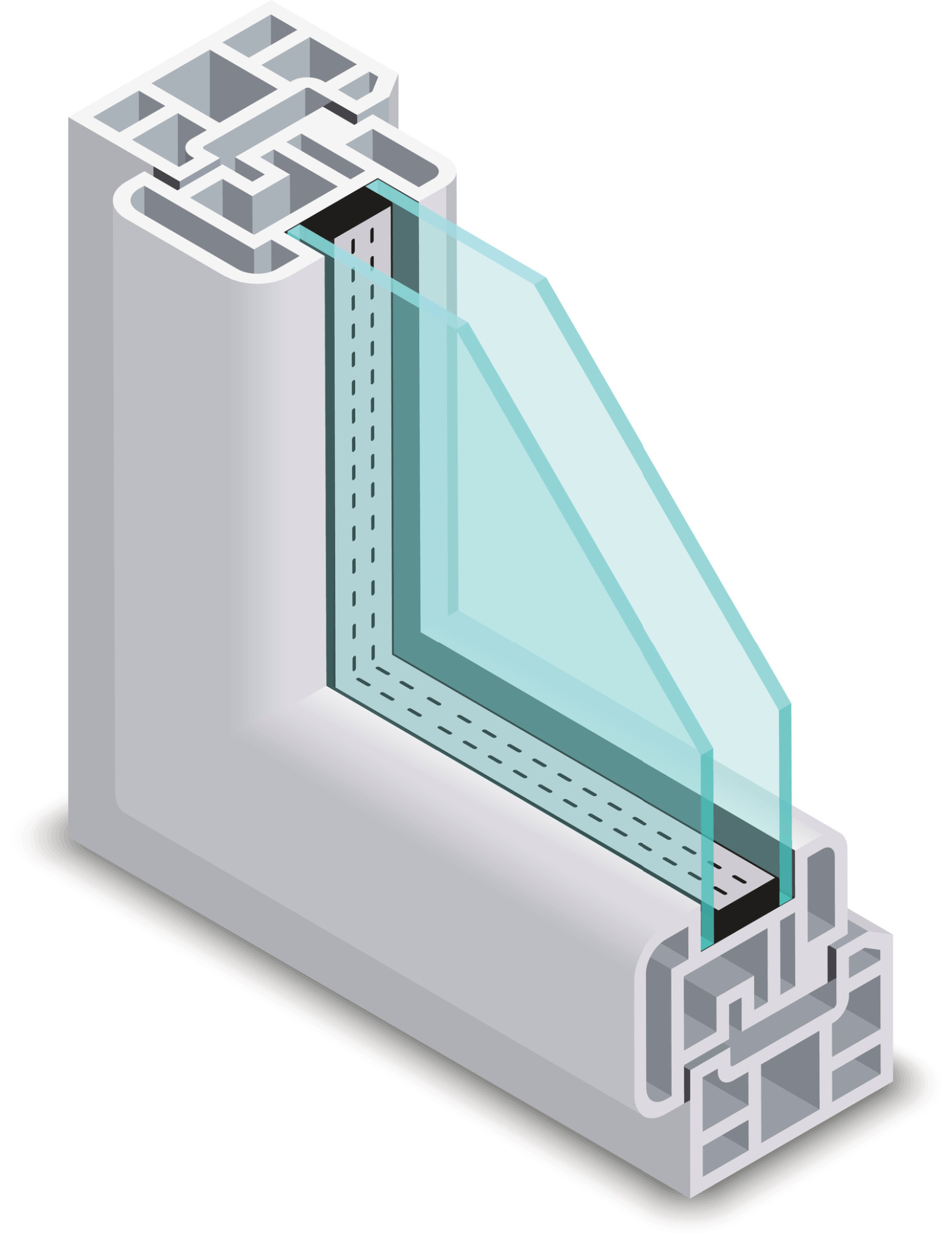

Double Glazed Units

Double Glazed Units are basically 2 panels of glass held together around the perimeter with a spacer and sealant to hold them apart. Most standard double glazed units are constructed with cavities around 16mm to 20mm and filled with Argon gas. The wide cavities are necessary to achieve the required insulation or U Value.

Double glazed units can be filled with air, but these days most double glazed units are filled with an inert gas: Argon or Krypton.

These gases, if used, remains still within the cavity and reduces the air movement in the gap between the panes and therefore increases the insulation effectiveness. As the space between the panes increases the movement of air or gas within the sealed unit can increase. There are design limits on cavity widths for air and inert gas filled units, and if these cavity widths are exceeded, internal convection occurs within the cavity and the insulation effectiveness reduces. Argon is a light gas and necessary for wider cavities. Argon cannot produce the best insulation in small cavities which require Krypton to provide the best results

Double Glazed Units (DGUs) are manufactured with glass in a range of thickness from 4 mm to 10 mm or more in special applications. Laminated or toughened glass may also be used as part of the construction.

The glass panes are separated by a 'spacer'. A spacer is the component, or piece, used in window manufacturing that separates the two panes of glass in a double glazed unit, and seals the air space between them.

Failed Double Glazed Units

The life of an DGU varies depending on the quality of materials used, size of gap between inner and outer pane, temperature differences, workmanship and location of installation both in terms of facing direction and geographic location.

Originally spacers were made of aluminium, but not only can they reduce the effectiveness as they act as a heat conductor, but this can lead to water or ice forming at the bottom of the sealed unit because of the heating/cooling loss through the window. These days newer materials are now used to combat the heat loss from aluminium spacer bars, and these are called 'Warm Edge' spacer bars.

For a traditional construction DG unit, condensation collects between the layers of glass when the perimeter seal has failed and when the desiccant has become saturated. This can only be eliminated by replacing the DGU.

Failure can be accelerated when there are large temperature differences between the inner and outer panes as this stresses the spacer adhesives which can eventually lead to it failing. Units with a small gap between the panes are more prone to failure because of the increased stress. A very badly failed unit can eventually fill with water.

If you require replacement Double Glazed Units...

Glass

Obscure Glass – Privacy Levels

Obscure glass is glass that transmits light but does not allow a view of objects on the other side, such as ground glass or frosted glass; translucent glass.

The degree of obscurity is measured on a scale of 1 to 5, where 1 offers very low levels of privacy and 5 offers very high levels of privacy.

See the link to the Pilkington Decorative Glass brochure here

Energy Efficient Glass

Energy efficient glazing is the term used to describe the double glazing or triple glazing use in modern windows in homes. Unlike the original single glazing or old double glazing, energy efficent glazing incorporates coated (low-emissivity) glass to prevent heat escaping through the windows. This makes the windows highly thermally insulating hence improving the energy efficiency of your home and helping to save money on your heating bills.

The Government approved Window Energy Ratings scheme rates windows on a scale from G being the lowest up to A+ being the most energy-efficient windows.